Mazak now offers its space-saving, high-performance VERTICAL CENTER NEXUS COMPACT 5X Vertical Machining Center as part of a self-contained, prefabricated automated cell that provides efficient, cost-effective lights-out manufacturing for small-to-medium sized parts. The cell incorporates – in addition to the full 5-axis Vertical Machining Center – a standalone robot and palletizer system for automated processing of up to 72 individual workpieces.

The automated cell handles a wide scope of workpiece sizes measuring up to 3.9” wide x 3.9” deep x 3.9” tall (75 mm x 75 mm x 75 mm) and weighing as much as 8.8 lbs (4 kg). For maximum production within a minimal amount of manufacturing floor real estate, the VCN COMPACT Automation Cell occupies 59” x 116.3” (1,498 mm x 2,946 mm) of floor space and the robot with stacker only 48” x 60” (1,219 mm x 1,524 mm).

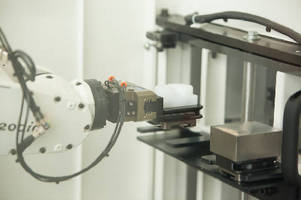

Operators – from outside the automated cell – use a two-position rotary carousel to load and unload workpieces mounted on System 3R pallets for storage in the cell’s 72-position magazine. A Fanuc LRMate 6-axis robot with two-jaw parallel gripper accesses any position in the pallet magazine, as well as the load/unload turntable, to load workpiece into the machine from either location for immediate production.

Once parts are loaded into the VERTICAL CENTER NEXUS COMPACT, which is available in 3- and 5-axis versions, the machine delivers absolute precise machining capability and superior part surface finishes. For power and versatility, the machine’s robust, high torque 12,000-rpm, 25-hp, CAT 40 spindle provides the aggressive performance required for tough materials, such as stainless steel, Inconel and titanium. An optional 40-hp, 20,000-rpm spindle, or 42,000-rpm, HSK E40 ultrahigh-speed spindle, are both also available.

Reduced part cycle times result from the machine’s three linear axes that attain high-speed rapid traverse rates of 1,417 ipm (36 m/min) and fast feedrates of 315 ipm (8 m/min). Plus, the VERTICAL CENTER NEXUS COMPACT accommodates 20 tools in its tool magazine (30 tools optional) to further increase part production versatility.

For rigid and precise 5-axis machining, Mazak’s rotary/tilt table on the VERTICAL CENTER NEXUS COMPACT is constructed with durable high-speed, backlash-free roller cam drive technology, allowing the table to rotate and tilt at speeds of 100 rpm and 75 rpm, respectively. The table, with an O.D size measuring 3.94” (100 mm) and I.D. of 1.57” (40 mm), tilts at angles from -20 to 120 and provides a holding torque of 249 ft-lbs and machining torque of 63 ft-lbs.

The VERTICAL CENTER NEXUS COMPACT features Mazak’s MX Hybrid Roller Guide System to deliver levels of durability and reliability that result in long-term accuracy. The MX Hybrid Roller Guide System dampens vibration to extend tool life, handles higher load capacities, accelerates and decelerates faster to shorten cycle times, eliminates tramp oil in the coolant by utilizing a greener grease-based lubrication system, and lasts longer with less required maintenance.

Mazak equips the VERTICAL CENTER NEXUS COMPACT with its advanced MATRIX 2 CNC control specifically for optimized 5-axis machining (3-axis machine versions are equipped with Mazak’s MATRIX NEXUS 2 CNC control). Within the MATRIX 2 control are both enhanced hardware and software functionalities that make the control easy to use while also delivering high accuracy and increased productivity. Control hardware performance is much faster with higher processing speeds for small increment operation, and a 5-axis spline interpolation function included in the control’s software provides smooth toolpaths from long block-by-block programs, easy tool vector control and shorter cycle times as well as superior 5-axis surface finishes. |